You might have heard of this popular idiom “an ounce of prevention is worth a pound of cure.” When it comes to the safety of your electrical equipment and appliances, this couldn’t be truer. A little knowledge about your appliances can go a long way.

Portable appliances are becoming more and more common in today’s society. These portable appliances are often used in our homes, offices, and on the go. It is important to test these appliances in order to ensure their proper functioning and prevent potential hazards. This article illustrates the basics of PAT testing that everyone must know.

What is portable appliance testing?

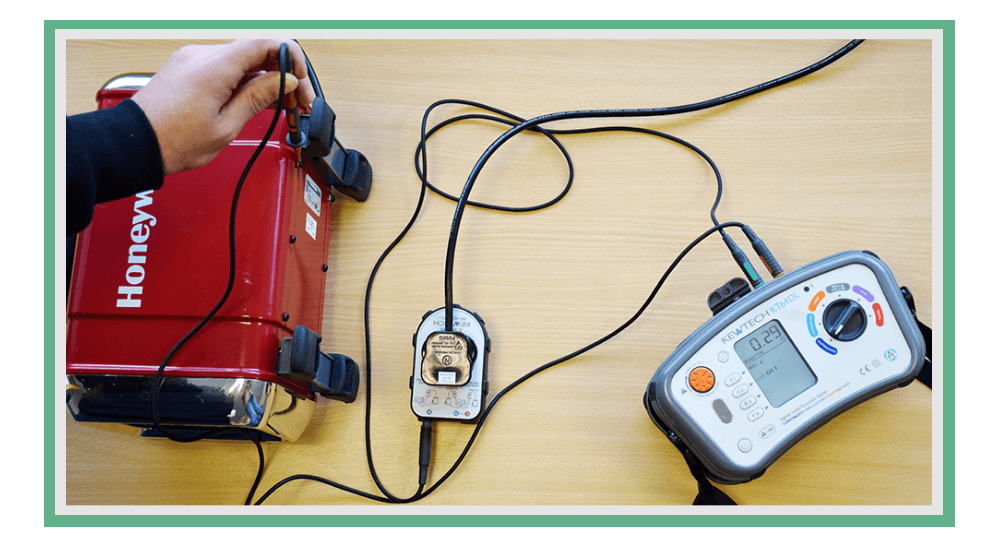

Portable appliance testing refers to the testing of appliances that are used in an off-site location. It is done to ensure that the appliances are functioning as intended and that they do not contain any dangerous materials. This process involves the use of portable testing equipment to test appliances for voltage, resistance and leakage.

This testing can be performed on a variety of appliances such as electric motors, compressors and heaters. PAT is done by a professional who has been trained in this field and will use various tools and equipment to test the appliance.

However, it is important to test your appliances in a laboratory that is certified and accredited. This ensures that the testing methods are accurate and reliable. Head on to this website to avail professional PAT testing services.

Basic things to know about PAT

How is PAT testing done?

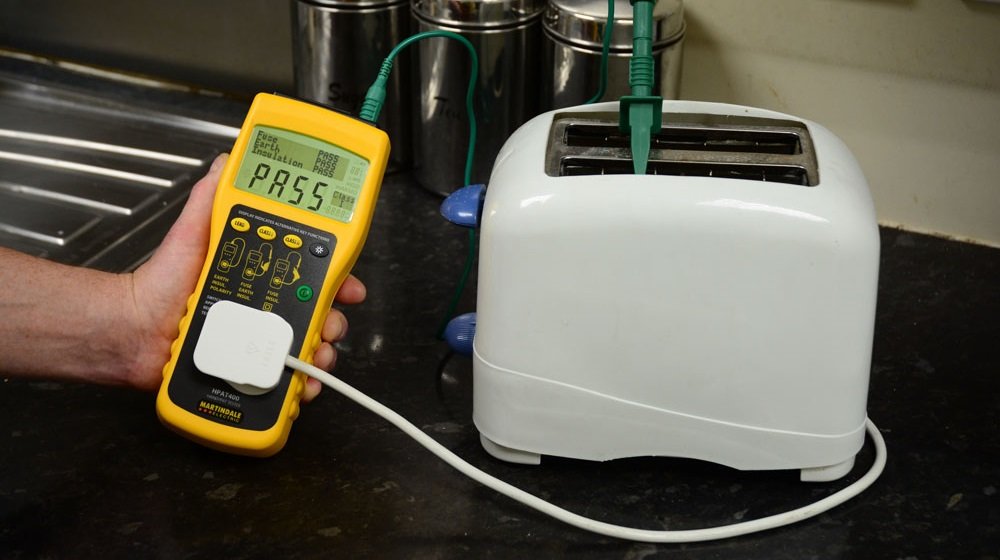

Portable appliance testing is the process of taking a portable electrical device and testing it to ensure that it remains in good working order. The test involves connecting the appliance to an electrical outlet, turning it on and off, and listening for any unusual sounds or other irregularities. If anything seems wrong with your appliance, then it should be repaired immediately to prevent any malfunctioning.

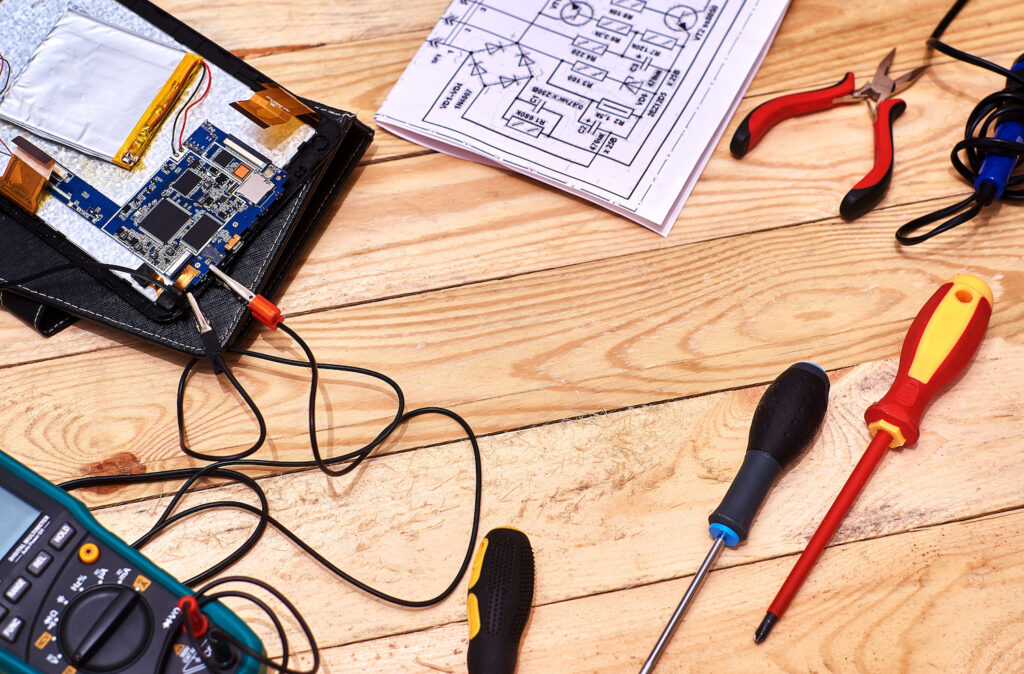

The first step in portable appliance testing is to determine whether or not there are any hazardous materials present in the appliance. The technician will look for any signs of corrosion, cracks, leaks or other damage that could indicate there may be an unsafe substance inside the appliance. If hazardous materials are found, they will be removed before further testing can take place.

After determining whether or not there are any hazardous materials present, the technician will check all parts of the appliance for wear and tear or damage. There may be some parts that have been damaged and need replacing before further testing can begin. If necessary, these parts can be replaced before additional testing begins.

Lastly, the technician will check for proper voltage levels across all wires within each part of the machine so that nothing malfunctions during testing. This includes ensuring that no wires break during shipping or power outages when using portable devices on site away from their primary location where they were originally manufactured.

After inspecting everything, if there aren’t any issues with your electrical equipment then you are good to go. But if there are any defects or malfunctioning then they must be fixed before it leads to an accident.

Portable Apparatus for Testing Machines

The main purpose of portable apparatus for testing machines is to test the voltage, resistance and leakage of electric motors. Portables are used in industrial applications where the strength of an electrical system must be tested before it is installed. These units are usually made up of three parts: a mounting bracket which holds the unit in place, a power supply which provides power to the unit, and an electrical measuring device which measures voltage, current and resistance.

There are two types of portable apparatus for testing machines i.e., bench top models and floor models. Bench top models are small enough to be easily moved around and stored when not in use whereas floor models have more room for storage space but cannot be moved easily due to their size or weight. The main difference between these two types lies in their size which makes them suitable for different applications depending on what type of application requires them.

Why is PAT testing important?

Portable appliance testing is important because it allows you to get a better understanding of your electrical equipment, and identify if there is any problem with it. This prevents accidents that can cause injury or death and ensures they are safe to use. If any electrical device starts acting up, PAT will help you to determine if it’s broken, and allow you to find the possible defects that can cause malfunctioning.

It also allows you to save money on repairing any defects or malfunctioning with your device before they become more expensive. In addition, PAT is also important because it provides you with valuable information about your product’s performance in real-world conditions. This information can help you improve your product and make it better suited for the needs of consumers.

Finally, PAT is also important because it helps protect both businesses and consumers from lawsuits that may arise from faulty products. By performing this type of testing on products before they are released into the market, you are able to ensure that no harm will come to either party as a result of using those products.

The Bottom-line

Whenever you are buying a new electrical device, don’t assume that it will work just fine once you plug it in and turn it on. PAT can help you find out whether your new appliance is capable of doing what it’s supposed to do before you make an expensive purchase.

You can avail of professional PAT services from any certified and reliable agency and get your appliances tested. However, PAT isn’t hard to do, and you can test it yourself if you have the basic knowledge of electrical appliances. To begin with, all you need is the right equipment, and you can find plenty of tutorials on social media helping you to test out each part of your appliance, so you can identify any issues and fix them by yourself.